This website uses cookies to improve your user experience. By continuing to use the site, you are accepting our use of cookies. Read our privacy policy.

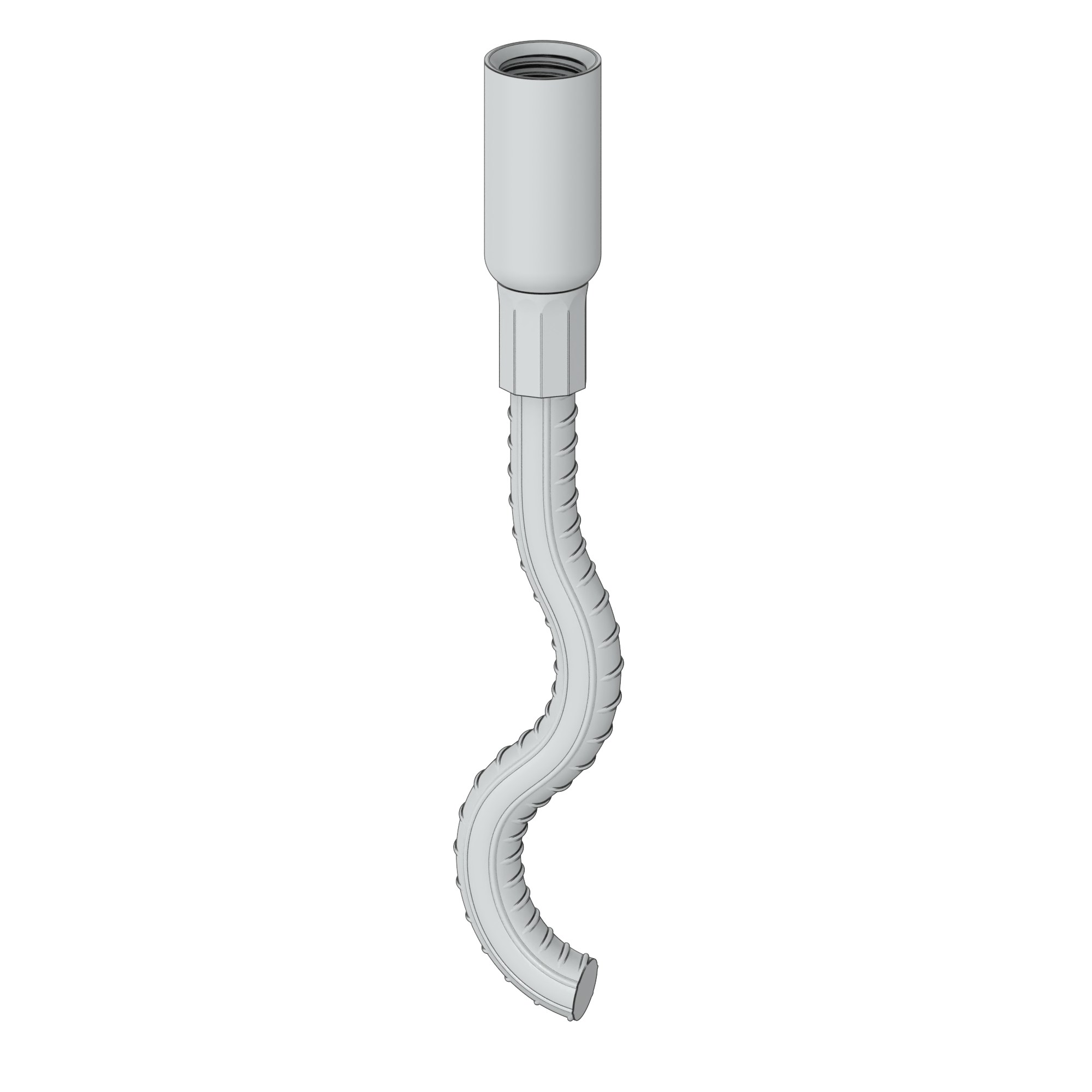

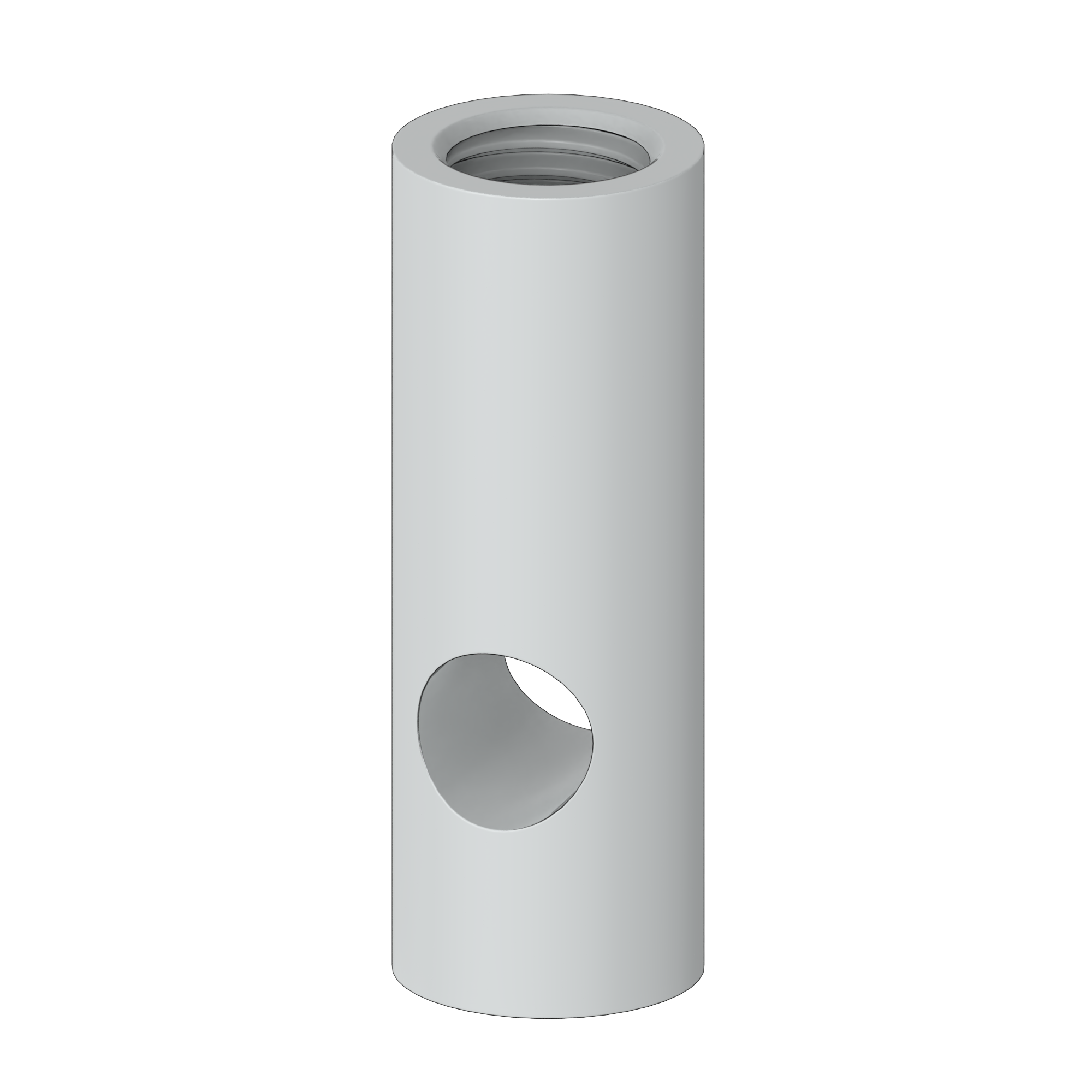

Decline Continue Solid cross hole socket BZP CFS BZP solid cross-hole socket is the ultimate solution for reliable and secure lifting operations in precast concrete including walls, panels and lifting precast beams and columns in bridge and frame construction. Unique cross-hole design allows easy and efficient threading of retention reinforcement. Also available in SS variant.

Contact us Overview Technical Resources 3 Accessories 6 Contact

Applications and features Applications:

Facade panels: lifting and fixing precast concrete panels. Retaining walls: lifting and fixing precast concrete walls. Bridge and frame construction: lifting and fixing precast beams and columns. Tunnels and shafts: lifting and fixing precast units on site and in the factory. Features:

The attaching reinforcement has a long tail that offers unparalleled anchorage in thin precast elements, ensuring maximum stability and durability. The socket has an M thread so can be used for lifting and fixing applications. Sold cross hole socket is considered an alternative to waved anchors and can be used based on the designer preferences.

Product variants Product variants Load class Dimensions Insulation parameters Profile size t [tn]Load group

Load range [kN]Load capacity group

Design load [kN]Vrd

Dowel [-] Depth [mm] L1 [mm]Embedded length

Load group [T] D [mm]Metric thread

L [mm]Length

D [mm]Diameter through foam

Lth [mm]Screw in depth

C1 [mm]Rebar hole diameter

x [mm]Depth

y [mm]Width

Fv, Fs [kN]Axial and Angled (under 30 degrees)

L2 [mm]Length

Ø D1 [mm]Diameter

Ø D2 [mm]Diameter

Ø D3 [mm]Diameter

L [mm]Length

c [mm] Rd [mm]Diameter

Lengths [mm]Available lengths

e [mm]Length

j [mm]Hole width

a1 [mm]Gap between holes

∠ Angle [°]Angle in degrees

C [mm]Hole to edge distance

Matching profileCompatible part

hp [mm]Profiling depth

Weight [kg/m]+-10%

e1 [mm]Length

Max supported height [mm] B [mm]Box width

Available colour Thermal conductivity [Wm°K] Load group [T] Max lateral load [kN] LSRH-12-42 0.5 12 50 23 11 LSRH-16-75 1.2 16 75 26 14 LSRH-20-75 2.0 20 75 33 18 LSRH-24-100 2.5 24 100 42 18 LSRH-30-125 4.0 30 125 54 22

Approvals and declarations VDI/BV-BS guideline 6205 and the European machine guideline 2006/42/EG UKCA and CE marked UK/EC Declaration of Conformity with EN ISO 12100:2010

Materials Component Material Description Socket E355 Solid steel tube to EN 10305 Coating BZP Bright Zinc Plated layer thickness of 4 to 6 μm

![Dimensions [mm]](https://cdn.sanity.io/images/y9uhquuo/production/6230f05733c9fc51117bcbe1aaefbec19f44f25d-1999x1407.png?auto=format&fit=max&dpr=2&q=80&w=3840&h=2703)