This website uses cookies to improve your user experience. By continuing to use the site, you are accepting our use of cookies. Read our privacy policy.

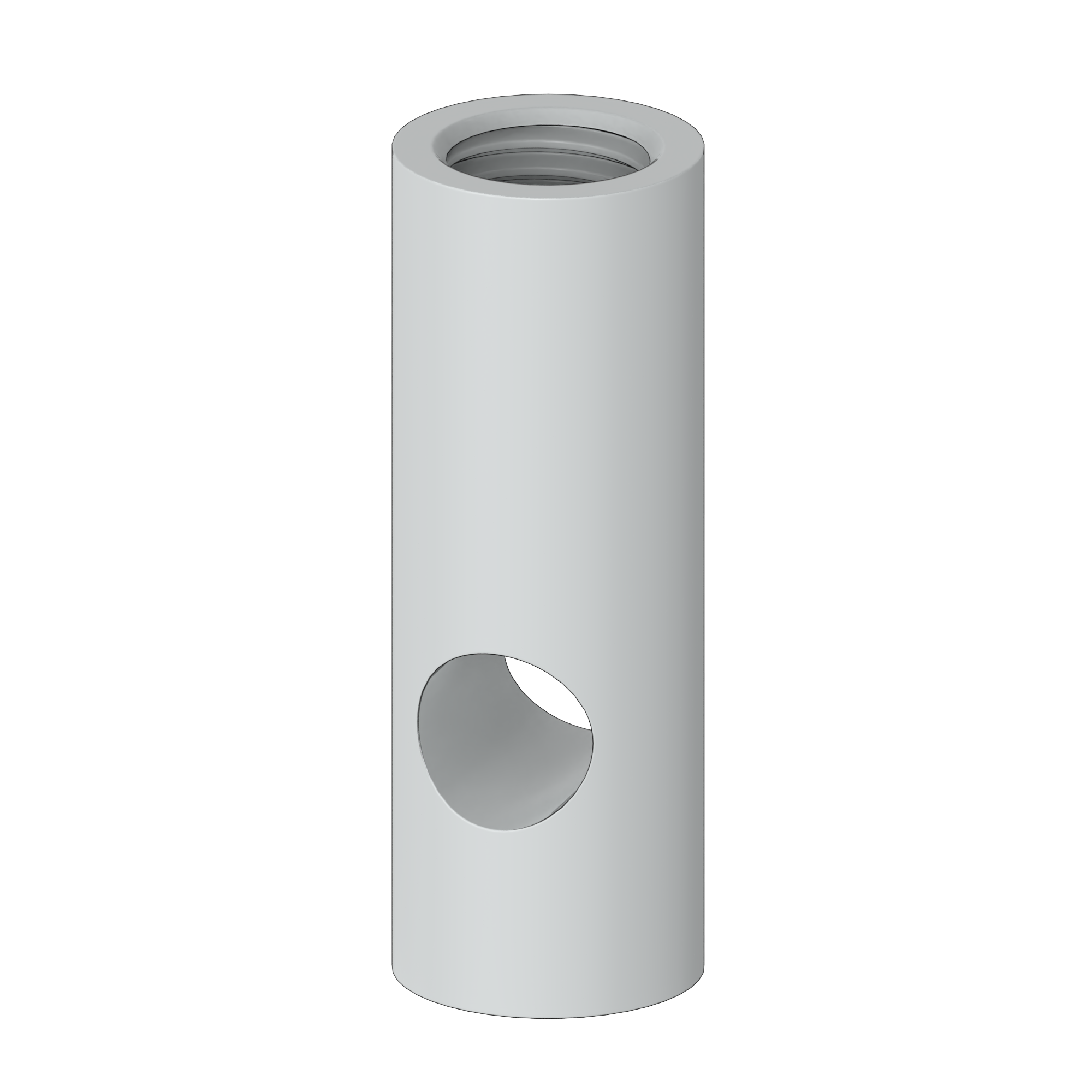

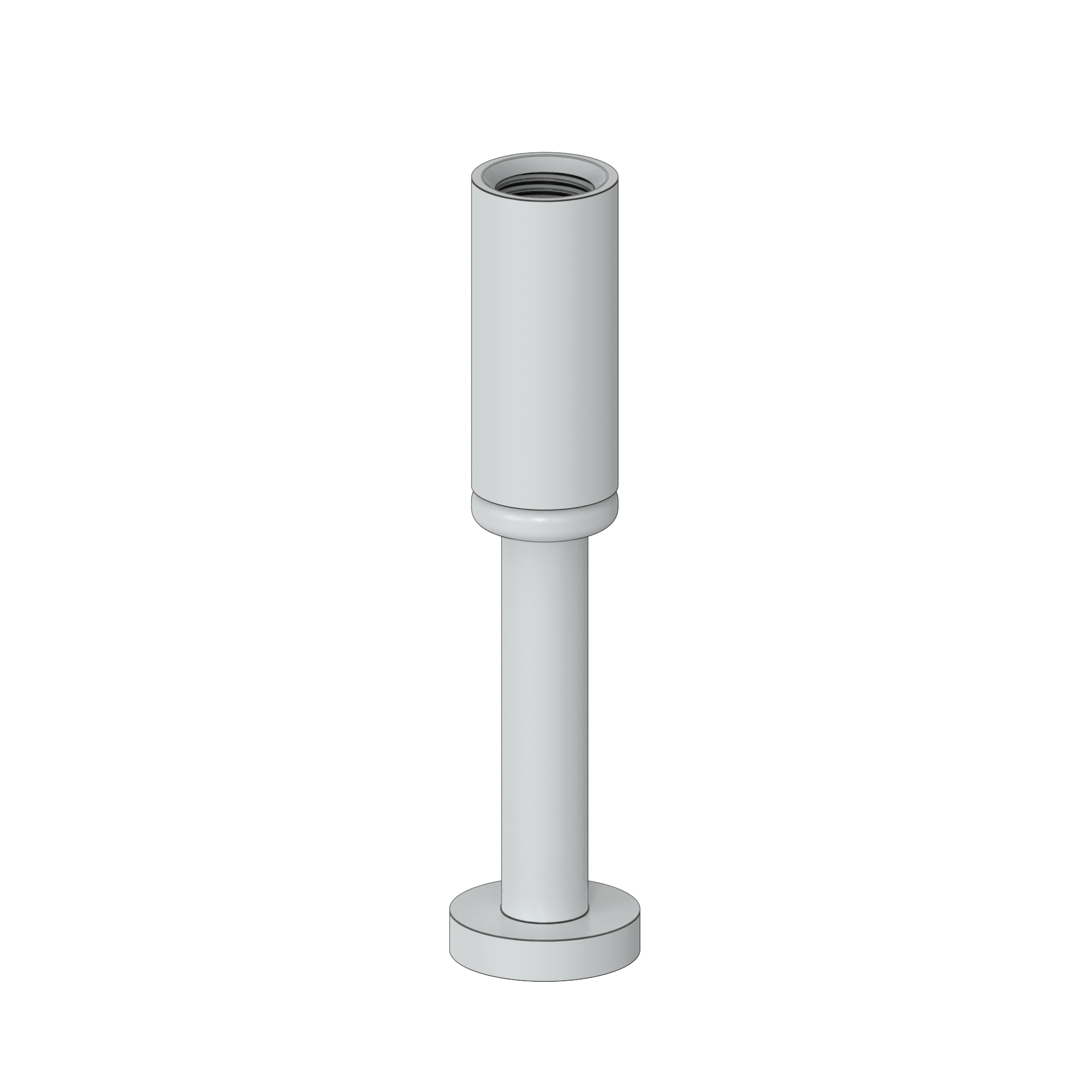

Decline Continue Friction welded stud anchor SS Built to withstand corrosion and designed for both high axial and transverse loads, this stainless steel FW anchor is ETA approved. It is perfect for fixing elements in a variety of applications including usage in cracked concrete, bridge construction, fixing facade panels and anchoring retaining walls.

Contact us Overview Technical Resources 3 Accessories 4 Contact

Applications and features Applications:

Bridge construction: Anchoring precast concrete bridge elements together, such as beams and columns. Facade panels: Precast concrete facade panels can be fixed to the building's steel or concrete structure. Retaining walls: Precast concrete retaining walls can be anchored using high-strength friction welded anchors. Features:

High resistance according to European Technical Assessment (ETA). Approved for use in cracked and uncracked concrete. High flexibility due to variable embedment depths. Higher corrosion resistance. Free FixPro design program.

Product variants Product variants Dimensions Profile size L1 [mm]Embedded length

D [mm]Metric thread

D1 [mm]Diameter

L [mm]Length

D [mm]Diameter through foam

Lth [mm]Screw in depth

LH [mm]Socket Length

Hef [mm]Minimum effective embedment depth

L [mm]Length

Rd [mm]Diameter

SL-FW-A4-M12-127 12 16 127 25 60 120 SL-FW-A4-M12-152 12 16 152 25 60 145 SL-FW-A4-M16-127 16 22 127 28 60 119 SL-FW-A4-M16-152 16 22 152 28 60 144 SL-FW-A4-M16-202 16 22 202 28 60 194 SL-FW-A4-M20-150 20 27 150 33 60 142 SL-FW-A4-M20-200 20 27 200 33 60 192 SL-FW-A4-M24-152 24 36 152 38 60 142 SL-FW-A4-M24-202 24 36 202 38 60 192 SL-FW-A4-M24-302 24 36 302 38 60 292

Approvals and declarations European Technical Assessment ETA-16/0918 CE Marked

Materials Component Material Description Socket 1.4401, 1.4404 or 1.4571 Stainless steel according to EN 10088-2 Component S235J2+C470 Steel grade according to EN 10025-2

![Product variants dimensions [mm]](https://cdn.sanity.io/images/y9uhquuo/production/f98e97df42bdeac58cb1c6a7d0c2858eac7a3b08-1909x1150.png?auto=format&fit=max&dpr=2&q=80&w=3840&h=2313)