What’s the difference between load groups and capacities?

‘Load groups’ is a term we hear a lot.

Technically speaking, a load group is a classification of the lowest possible load in any direction that something can take. So, if a lifting socket is rated to 2.5T, it can take 2.5T in the worst possible direction, which in the vast majority of cases would be shear.

The problem with load groups is that they represent an old-fashioned – and, ultimately, inefficient – way of looking at things.

Historically, load groups have been used to match up sockets with the correct lifter, for instance in the case of a female-threaded socket and a male-threaded lifter. In this day and age, this is the only way in which using load groups may be advantageous – making sure that if you have a 2.5T lifting socket, it’s matched up with a compatible 2.5T eye.

But in the vast majority of cases, we should be looking at the capacity instead.

What are capacities?

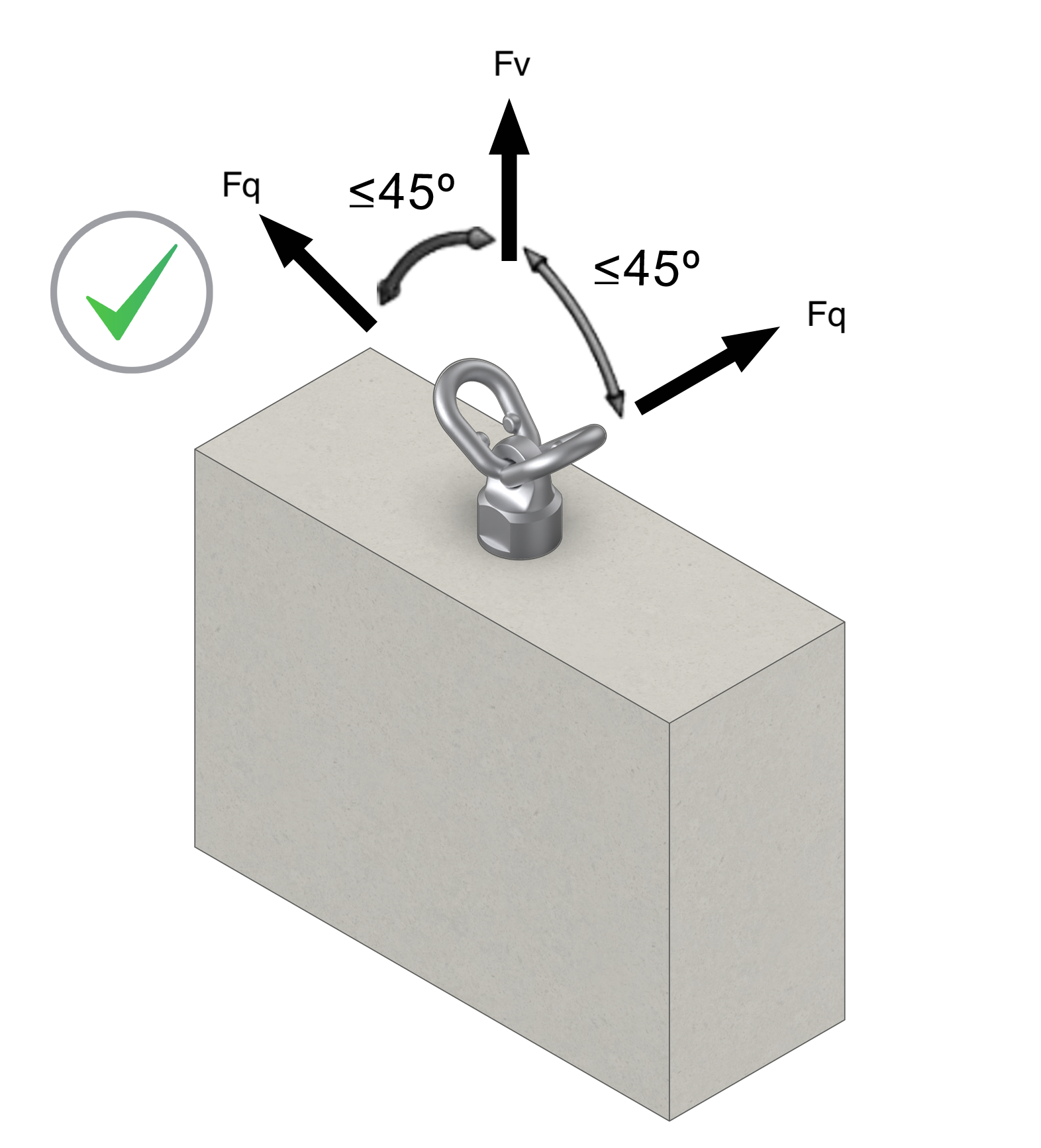

Whereas load groups simply indicate that if all of the perfect conditions are met, you will have a certain minimum load in any direction, capacities refer to the breakdown of the different concrete conditions you’re installing and the capacity of the lifter given those conditions. It’s therefore possible that a lifter which is rated at 6.3T is actually capable of taking more (or less) than this load, depending on the concrete strength, edge distance and the direction of the load applied.

The industry has a hard time getting to grips with this way of thinking, largely because we’ve become used to talking about load groups as default for so many years. If someone has a 2.5T lifting eye, they usually aren’t interested in whether they have a small or significant edge distance or thickness. They’ll simply say that they can take 2.5T.

But if the industry were to move away from load groups, and understand that actually it’s capacities we should be thinking about, those same people would soon find that there are numerous benefits to be gained.

How can knowing the difference add value?

Most estimators who are involved with large contracts will be dealing in load groups. As a result, they are at risk of over-specifying a significant proportion of their lifters, because those lifters have been chosen using a one-size-fits-all approach.

There are two main ways in which this is inefficient. The first is the resulting carbon footprint of using a larger lifter than is necessary. The second is cost. By looking at capacities instead of load groups, you’re looking at the actual concrete conditions you have available, and can therefore identify a smaller lifter which could be used more efficiently. It’s about looking for opportunities to use a smaller product, such as a 2.0T lifter, where you might previously have used a 6.3T lifter.

In essence, by ensuring you aren’t using larger equipment than you actually need, you’re reducing your carbon footprint and will likely also save money. And that, when all’s said and done, is why it’s so important to understand the difference between capacities and load groups.

If you need help ensuring the product you’re using is the correct size, contact our technical team on technical@cfs-fixings.co.uk